ISO/IEC 17025:2017

ASTM E84 Tunnel Test

ASTM E84 Tunnel Test

The Steiner Tunnel test, more commonly referred to as the ASTM E84 Tunnel Test, is a fire-test-response standard for the comparative surface burning behavior of various building materials. The ASTM E84, UL 723, and ASTM E2768 (extended 30-minute test) are the most common tests utilizing the Steiner Tunnel furnace, the results of which, provide comparative measurements of surface flame spread and smoke density. There are several ways these results are used, with the three most common being product development, customer and market acceptance, and evidence for code compliance.

Who and Why?

American tragedies such as the 1942 Cocoanut Grove nightclub fire in Boston, Massachusetts, the 1946 LaSalle Hotel fire in Chicago, Illinois, and the 1946 Winecoff Hotel fire in Atlanta, Georgia led to research into the flammability of building materials, combustibility, detection, and occupancy. Building codes for new and existing structures were updated and new codes to recognize flashover as a means of fire propagation were adopted. The adoption of the Steiner Tunnel and National Fire Protection Agency (NFPA) 101® Life Safety Code® are directly related to these historic events.

Since 1961 building materials have been tested using the ASTM E84 method in the Steiner Tunnel, and prior to that using the Underwrites Laboratory, Inc. U.L. 723 Standard. Products tested include interior finish materials such as gypsum wallboard, fiber cement, wall coverings, wall papers and vinyls, wood paneling, wood structural panels, plastics, foam plastics, composite siding, expanded polystyrene, spray polyurethanes and polyisocyanurates, various insulations, paints, coatings, caulks, tapes, and flame-retardant materials. Test samples may be mounted for testing as an unadhered material with or without support, adhered with glue or fasteners to various substrates or as a composite sample depending on the end use or application of the material. Many mounting methods are covered in the mandatory annexes of the ASTM E84 standard.

Product manufacturers may be using the test data for several different reasons. The data may feed into their research and development process, helping them refine an innovative solution to market needs. The product may already be developed, but a customer may have a unique application that now requires test data to satisfy regulations, building code officials, project specifications, codes, or standards.

Procedure of test

An ASTM E84 tunnel test requires a 24-inch-wide x 24-foot-long conditioned sample mounted inverted on the ceiling under a removable lid. A regulated induced draft system provides for the movement of air and products of combustion within the tunnel furnace. The methane gas burners deliver the metered test flame upward against the surface of the sample for the 10-minute duration of the test. The surface burning progress of the flame is then monitored through viewports on one side of the furnace, measuring the distance-time relationship of the flame spread across the test specimen’s surface. The smoke data system uses a vertically oriented photometer system measuring light obscuration as the sample burns. The surface burning data points and light obscuration data points are recorded and used to calculate the Flame-Spread Index (FSI) and Smoke-Developed Index (SDI) respectively.

Results of Tests

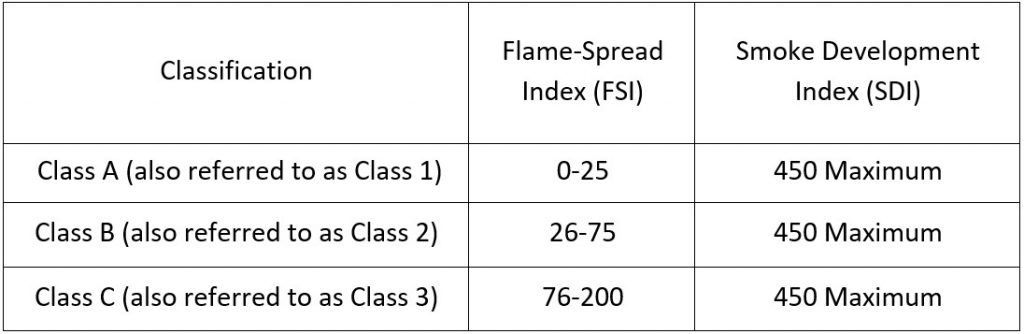

After performing the ASTM E84 tunnel test on a specimen, the Flame Spread Index (FSI) and Smoke-Developed Index (SDI) numbers will be generated. The Flame Spread Index (FSI) is a unitless value that provides a comparative measure of how fast the flame front spreads along the surface and how far it travels down the tunnel in comparison to calibration materials (red oak and fiber-cement board). The calculated numerical Flame Spread Index (FSI) is rounded to the nearest multiple of five and reported in the results section of the final report. The Smoke-Developed Index (SDI) measures the amount of smoke a sample emits as it burns in comparison to calibration materials (heptane and fiber-cement board). The calculated numerical Smoke-Developed Index (SDI) is rounded to the nearest multiple of five or, in the case of indexes of 200 or more, the nearest 50, and reported in the results section of the final report. Since the standard has no “pass” or “fail” criteria, certain codes and regulations define a required Flame Spread Index (FSI) and/or Smoke-Developed Index (SDI) for a particular application or installation. Building Codes such as the International Building Code (IBC) specify “interior wall and ceiling finishes shall be classified in accordance with ASTM E84.” Additionally, the National Fire Protection Agency (NFPA) 101® Life Safety Code® require that “Interior wall or ceiling finish that is required elsewhere in this Code to be Class A, Class B, or Class C shall be classified based on test results from ASTM E-84, or UL 723.”

Testing Fees

Commercial Testing Company is not specialized and, due to the variety of tests performed on many different materials, does not have a formal price list. All testing fees are quoted individually upon request. For your particular interest, please call 706-278-3935 and permit us to provide you a quotation.

For more information on testing services Please contact us today!

Contact

Phone: 706-278-3935

Fax: 706-278-3936

Email: Information@CommercialTesting.com

Business Hours:

Monday - Friday

8:30 AM - 5:00 PM

The name of COMMERCIAL TESTING COMPANY shall not be used under any circumstances in advertising to the general public without prior written consent of Commercial Testing Company. Tested To Be Sure® is a Registered Trademark of Commercial Testing Company, shall not be used in part or in whole under any circumstances by the general public without prior written consent of Commercial Testing Company.

© 2020 Commercial Testing Company, Inc.